WATER RESISTANT, WATER REPELLENT or WATERPROOF? Which is best?

What is the difference between a waterproof bag, water resistant or water repellent bag?

Chances are if you have started looking for gear that is going to meet the needs of a potentially wet adventure, you are going to come across products that are either labeled Waterproof, Water Resistant or even Water Repellent. Understanding the three could be the difference between a enjoyable outdoor experience and mild case of hypothermia. Let’s define each of these levels by the books. Here is what Webster.com states:

- Waterproof - Impervious to water.

- Water Resistant - designed to not be easily harmed or affected by water or to not allow water to pass through easily

- Water Repellent - treated with a finish that is resistant but not impervious to penetration by water

These 3 definitions broadly explain the what each term means but what you will find as you start searching for gear that it isn’t always that cut and dried. Let’s break down what each one means as you navigate the vast collection of gear on the market to figure out what one is best suited to offer the function you need on your next adventure.

Waterproof Bags

As stated in the definition, waterproof means impervious to water which from a definition standpoint usually refers to the material used to construct the gear, however it is important to recognize that impervious materials can be constructed in ways that are more waterproof than others. The most common materials used to construct waterproof bags are PVC (Polyvinyl chloride) and TPU (Thermoplastic Polyurethane). These plastics are laminated onto fabrics that have varying thread counts. You will often see this referred to in product descriptions as Denier. For example, you may see a dry bags that range from 60D to 1000D. The higher the number, the stronger the bag will be. These fabrics can be sewn, glued, melted or welded together.

The degree of waterproofing will depend upon how the product is constructed. For example, if you were to buy a bag or a backpack made from 200D PVC, but the seams are stitched, it can be assumed (unless the seams are taped, which we will talk about later) that the bag is more water-resistant than waterproof because stitched seams can allow water to enter the bag if were to be submerged in water.

The most common method of constructing waterproof bags is through a method called RF-Welding (Radio Frequency Welding) but it also called HF Welding (high-frequency welding) or Dielectric welding. This method uses electromagnetic energy to fuse the materials together and this has become the industry standard to constructing waterproof bags. If a bag is constructed in this method, it is considered waterproof as the fabric and the seams are both impervious to water.

Just because a bag is constructed with waterproof materials and is constructed with high-frequency welds does not mean that it will be 100% waterproof. It is important to consider how the bags, duffels or backpacks will open and close as the type of closure will determine just how waterproof the bag will be in a water-submersion situation.

The most common way that waterproof bags are closed are what is typically called ‘roll-top closure’. Dry bags and waterproof bags are almost always top-access bags and in order to close or seal the bags, they need to be rolled or folded and then clipped together or to the pack. For the best waterproof seal on a roll-top bag it is better to fold/crease and clip the bag than to casually roll and clip. Here is a link to a tutorial we made on how to properly close a roll-top bag. Even though roll top bags are very effective at keeping gear dry in quick submersion and super wet situations, there is a chance that water can still seep in through the rolled/folded section of the bag if submerged for longer periods of time.

(roll-top closure)

Another method of closing dry bags and waterproof bags is with a waterproof zipper. Waterproof zippers (good ones) are extremely effective at keeping bags waterproof and in most circumstances are more effective than roll-top bags. However there are some drawbacks to waterproof zippers. First and foremost they are very expensive. In some cases, the zipper can cost the manufacturer nearly as much as the rest of the bag construction. The most popular waterproof zippers are manufactured by YKK and a T-Zip (a German Company). Secondly, waterproof zippers require maintenance and will stop working if you do not meticulously care for them by keeping them clean and lubricated. If you are extra careful (OCD) with all of your gear, then a waterproof zipper closure might be for you.

Another method of closure is similar to a zip-lock closure. Essentially the top closure of the dry bag is closed in the same way a freezer storage bag would be closed except in a much more heavy duty fashion and this is also an extremely effective method of waterproofing and is equally as waterproof as the waterproof zipper closure and more waterproof than a roll-top closure as this effectively seals the bag completely. Similar to waterproof zipper closures, the zip-locking closures are also a bit higher-maintenance in that you have to be sure to clean and lubricate the closures to ensure that they don’t become too difficult to open and close over time.

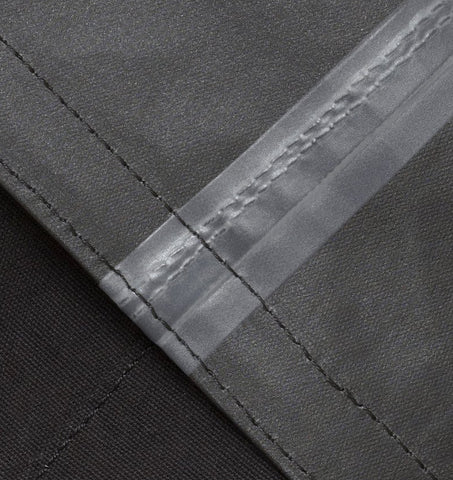

Finally another method of waterproofing is using stitched waterproof materials with seam taping. This is very common in waterproof clothing as it enables manufacturers to create more complex designs because they can use waterproof seam tape on the sewn seams. Seam taping can be very effective at waterproofing bags as well and is often used in ultralight dry bags. The drawback with seam taping is that over time the seam taping is not as durable as a RF Welded seam so the lifespan of a taped seam is going to likely be shorter than the alternative.

(waterproof seam tape)

Water Resistant Bags

With waterproofing figured out, we can now move to the next type of bag. Water Resistant bags will shed light amounts of water because of the weave of the fabric, however because the bags are woven and sewn and used zipper closures rather than coated and welded with roll-top closures, the bags will eventually take on water. So if you plan on spending a lot of time on the water or in the water, a water resistant bag is not the best choice for protecting your gear unless your gear is ok in the water.

Water Repellant Bags

Water repellant bags will do better at keeping your stuff dry than a water resistant bag as the fabric used to make the bag is often coated with a silicone spray, scotch guard or wax coating in order to make water bead on the surface. These coatings are very effective at keeping light amounts of water out of your bag but because most water repellant bags have traditional flap, velcro or zipper closures, they are not going to be useful if your bag was to be dropped or set down in standing water or deep water.

(waxed canvas water-repellant bag)